| 品牌高必盛 | 有效期至长期有效 | 最后更新2024-10-18 11:26 |

| 压铸机吨位238吨 | 合模力2380KN | 射料力300KN |

| 浏览次数1039 |

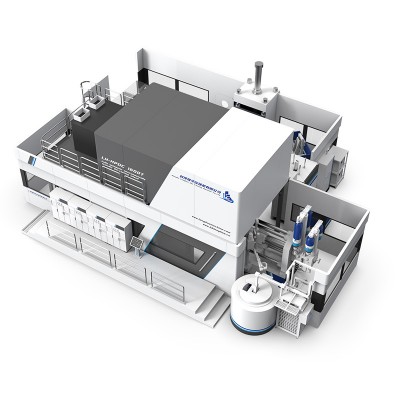

238吨卧式冷室铝合金压铸机设备、卧式压铸机

东莞市高必盛压铸智能装备有限公司专业研发与定制生产锌合金压铸智能自动化机械设备、压铸自动取件机、上下料机械手、高速伺服取件机、输送机、输送带、压铸全自动水口分离机、超声波抖水口机、自动切水口机器等等其他先进的智能化机械设备。

高盛-高必盛压铸机技术参数表(冷室)

高盛-高必盛压铸机技术参数表(冷室)

GBS die casting machine parameter table (cold room)

|

配置项目 Configuration item |

单位 |

DC180T |

DC230T |

DC238T |

DC300T |

DC350T |

DC380T |

DC400T |

DC550T |

DC700T |

DC800T |

DC900T |

|

合模力 Clamp force |

KN |

1800 |

2300 |

2380 |

3000 |

3500 |

3800 |

4000 |

5500 |

7000 |

8000 |

9000 |

|

合模行程 Clamping stroke |

mm |

375 |

400 |

400 |

460 |

500 |

520 |

550 |

600 |

650 |

760 |

760 |

|

顶出力 Ejecting force |

KN |

120 |

170 |

170 |

150 |

150 |

285 |

285 |

315 |

315 |

320 |

320 |

|

顶出行程 Ejection stroke |

mm |

100 |

100 |

100 |

105 |

105 |

125 |

125 |

120 |

150 |

180 |

180 |

|

模具厚度 Mold thickness |

mm |

220-650 |

220-670 |

220-670 |

250-700 |

250-700 |

250-700 |

250-750 |

350-850 |

300-900 |

400-950 |

400-950 |

|

模板尺寸 Platen size(HxH) |

mm |

700x810 |

760x800 |

820x820 |

900x900 |

940x940 |

1000x1000 |

1050x1050 |

1160x1160 |

1270x1300 |

1400x1360 |

1450x1415 |

|

导柱直径 Diameter of guide |

mm |

85 |

95 |

100 |

110 |

120 |

130 |

130 |

140 |

160 |

180 |

180 |

|

Tiebar spacing(WxH) |

mm |

475x445 |

520x520 |

530x530 |

580x580 |

620x620 |

650x650 |

700x700 |

780x780 |

850x850 |

910x910 |

960x960 |

|

压射力 Force of shot |

KN |

255 |

300 |

300 |

370 |

405 |

405 |

405 |

460 |

610 |

665 |

665 |

|

压射行程 Stroke of shot |

mm |

340 |

390 |

390 |

430 |

500 |

500 |

570 |

600 |

670 |

760 |

780 |

|

锤头直径 Punch diameter |

mm |

40/50/60 |

50/60/70 |

50/60/70 |

50/60/70 |

60/70/80 |

60/70/80 |

60/70/80 |

70/80/90 |

80/90/100 |

80/90/100 |

90/100/110 |

|

Shot volume |

Kg |

0.9/1.2/1.8 |

1.42/2.2/2.8 |

1.42/2.2/2.8 |

1.57/2.2/3.0 |

2.7/3.6/4.8 |

2.7/3.6/4.8 |

3.0/4.1/5.1 |

4.3/5.6/7 |

4.3/5.8/7.2 |

7.2/9.1/11.2 |

9.1/11.2/12 |

|

Shot volume |

Kg |

2.1/2.7/3.9 |

2.8/4.5/5.1 |

2.8/4.5/5.1 |

3.3/4.8/6.0 |

5.7/7.8/10.2 |

5.7/7.8/10.4 |

6.6/8.7/11.1 |

8.1/11.4/13.1 |

9.9/12.6/16.5 |

12.6/16.5/18.3 |

16.5/18.3/21.6 |

|

Casting pressure (pressurized) |

Mpa |

202/129/90 |

148/104/75 |

148/104/75 |

162/113/83 |

145/106/82 |

145/106/82 |

145/106/82 |

122/93/74 |

159/122/96 |

133/105/85 |

154/121/98 |

高必盛压铸机技术参数表(冷室)

GBS die casting machine parameter table (cold room)

|

配置项目 Configuration item |

单位 |

DC180T |

DC230T |

DC238T |

DC300T |

DC350T |

DC380T |

DC400T |

DC550T |

DC700T |

DC800T |

DC900T |

|

铸造面积 Casting area |

CM2 |

72/120/175 |

145/210/284 |

145/210/284 |

182/262/358 |

275/375/490 |

275/375/490 |

320/450/550 |

405/535/680 |

395/515/655 |

590/750/925 |

580/740/915 |

|

最 大铸造面积 Maximum casting area |

CM2 |

400 |

600 |

620 |

780 |

1045 |

1085 |

1150 |

1250 |

1650 |

2000 |

2350 |

|

压射位置 Shot position |

mm |

0.-140 |

0、 -70、 -140 |

0.-140 |

0.-160 |

0.-175 |

0.-175 |

0.-200 |

0.-250 |

0.-250 |

0.-250 |

0.-250 |

|

压射头推出距离 Launch distance of shot head |

mm |

120 |

140 |

140 |

150 |

180 |

180 |

200 |

220 |

250 |

300 |

300 |

|

压射室法兰直径 Shot chamber flange diameter |

mm |

110 |

110 |

110 |

110 |

110 |

110 |

110 |

165 |

165 |

200 |

200 |

|

压室法兰凸出高度 Shot flange protruding plate height |

mm |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

15 |

15 |

20 |

20 |

|

电机功率 Motor power |

KW |

15 |

15 |

15 |

22 |

22 |

22 |

22 |

30 |

37 |

45 |

45 |

|

系统压力 System pressure |

MPa |

14 |

14 |

14 |

14 |

14 |

14 |

15 |

15 |

16 |

16 |

16 |

|

油箱容量 Oil tank volume |

L |

600 |

600 |

600 |

800 |

800 |

800 |

900 |

1100 |

1100 |

1200 |

1200 |

|

机器重量 Weight of machines |

Ton |

6.5 |

7.5 |

8.5 |

11.5 |

14 |

15.5 |

17 |

25 |

30 |

40 |

45 |

|

机身尺寸 Size of body shape(L×W×H) |

mm |

5490x1200x2600 |

5600x1300x2600 |

5600x1300x2600 |

6350x1410x2700 |

6500x1600x2800 |

6500x1600x2800 |

6800x1700x2900 |

7500x1950x2800 |

7500x2000x3200 |

8660x2010x3000 |

9700x2100x3000 |

高必盛GOBESUN 锌合金压铸机参数(热室)

Parameter table of GBS die casting machine(hot chamber)

|

配置项目 Configuration item |

单位 UNIT |

DM25T |

DM28T |

DM30T |

DM38T |

DM50T |

DM50TC |

DM68T |

DM90T |

DM130T |

DM168T |

DM230T |

DM300T |

DM400T |

DM600T |

|

控制系统PLC |

品牌Brand |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

欧姆龙Omron |

|

显示屏display |

品牌、尺寸Brand & Size |

台达 7寸Delta 7inch |

台达 7寸Delta 7inch |

台达 7寸Delta 7inch |

台达 7寸Delta 7inch |

台达 7寸Delta 7inch |

台达 7寸Delta 7inch |

台达 7寸Delta 7 inch |

台达 7寸Delta 7inch |

台达10寸Delta 10inch |

台达10寸Delta 10inch |

台达10寸Delta 10inch |

台达10寸Delta 10inch |

台达10寸Delta 10inch |

台达10寸Delta 10inch |

|

伺服系统Servo system |

品牌Brand |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

蒙德Maigoo |

|

合模力 Clamp force |

KN |

250 |

280 |

300 |

380 |

500 |

500 |

680 |

900 |

1300 |

1680 |

2380 |

3000 |

4000 |

6000 |

|

合模行程 Clamping stroke |

mm |

135 |

165 |

190 |

190 |

200 |

200 |

215 |

300 |

350 |

360 |

400 |

460 |

550 |

600 |

|

顶出力 Ejecting force |

KN |

25 |

25 |

40 |

40 |

45 |

45 |

45 |

70 |

90 |

108 |

150 |

150 |

285 |

300 |

|

顶出行程 Ejection stroke |

mm |

40 |

40 |

45 |

45 |

45 |

45 |

45 |

60 |

85 |

85 |

100 |

105 |

125 |

130 |

|

模具厚度 Mold thickness |

mm |

120-230 |

120-250 |

120-300 |

120-300 |

120-330 |

120-330 |

120-330 |

130-430 |

170-490 |

200-520 |

220-670 |

250-700 |

250-750 |

250-800 |

|

模板尺寸 Platen Size(W×H) |

mm |

390x370 |

410*410 |

450x400 |

450x430 |

550x435 |

455x455 |

565x500 |

600x660 |

660x720 |

720x770 |

820x820 |

900x900 |

1050x1050 |

1100x1100 |

|

导柱内距 Tiebar spacing(WxH) |

mm |

278x232 |

260*260 |

300x250 |

300x280 |

335x285 |

300x300 |

360x320 |

400x400 |

440x440 |

486x486 |

530x530 |

580x580 |

700x700 |

750x750 |

|

导柱直径 The diameter of Tiebar |

mm |

40 |

45 |

50 |

50 |

55 |

55 |

63 |

70 |

80 |

85 |

100 |

110 |

130 |

130 |

|

射料位置 Position of shot material |

mm |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0/-80 |

0/-80 |

0/-140 |

0/-160 |

0/-175 |

0/-175 |

|

射料力 Force of shot material |

KN |

30 |

30 |

55 |

55 |

55 |

55 |

55 |

90 |

108 |

108 |

130 |

160 |

180 |

200 |

|

射料行程 Stroke of shot material |

mm |

85 |

85 |

105 |

105 |

110 |

110 |

110 |

130 |

145 |

150 |

175 |

200 |

230 |

250 |

|

离咀行程 Stroke far from nozzle |

mm |

0-280 |

0-330 |

0-330/230 |

0-330/230 |

0-330/230 |

0-330/230 |

0-330/230 |

230 |

280 |

280 |

320 |

320 |

320 |

350 |

|

锤头直径 Punch diameter |

mm |

38 |

38 |

42 |

42 |

45 |

45 |

45 |

45/50/55 |

60/65 |

60/65/70 |

60/65/70 |

70/80 |

70/80/90 |

70/80/100 |

|

射料量/锌 Weight of shot material/Zn |

Kg |

0.38 |

0.38 |

0.7 |

0.7 |

0.9 |

0.9 |

0.9 |

1.0/1.26/1.53 |

2.1/2.4 |

2.1/2.4/2.86 |

2.5/2.9/3.3 |

3.8/5 |

4.4/5.5/7.2 |

5.5/6.5/8.3 |

|

坩埚容量/锌Capacity of crucible/Zn |

Kg/Zn |

150 |

200 |

360 |

360 |

360 |

360 |

480 |

480 |

480 |

480 |

480 |

480 |

480 |

480 |

|

电机功率 Motor power |

KW |

5.5 |

5.5 |

7.5B |

7.5B |

7.5B |

7.5B |

7.5B |

11 |

15 |

15 |

15 |

18.5 |

22 |

25 |

|

系统工作压力 System working pressure |

MPa |

8.5 |

8.5 |

8.5 |

8.5 |

9 |

9 |

9 |

11 |

14 |

14 |

14 |

14 |

14 |

16 |

|

熔炉 Furnace(oil) |

Kg/h |

1.8 |

1.8 |

3.5 |

3.5 |

3.5 |

3.5 |

3.5 |

4.8 |

4.8 |

4.8 |

6.3 |

6.3 |

11.2 |

13 |

|

电炉 Electric furnace |

Kw |

12 |

12 |

18 |

18 |

18 |

18 |

18 |

30 |

30 |

30 |

42 |

42 |

70 |

80 |

|

油箱容量 Oil tank volume |

L |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

250 |

300 |

300 |

400 |

500 |

800 |

800 |

|

射咀加热功率 Shot nozzle heating power |

Kw |

1.5 |

1.5 |

1.5 |

1.5 |

2 |

2 |

2 |

2 |

2.5 |

2.5 |

4 |

5 |

5 |

6 |

|

机器重量 Weight of machines |

KGS |

2000 |

2150 |

2300 |

2300 |

3300 |

3400 |

3400 |

5300 |

5800 |

6150 |

8100 |

11000 |

17000 |

18000 |

|

机身尺寸 Size of body shape(L×W×H) |

mm |

2950x1400x1850 |

3100x1500x2000 |

3100x1500x2000 |

3100x1500x2000 |

3150x1500x2050 |

3150x1500x2050 |

3150x1500x2100 |

4660x1690x2270 |

4500x1500x2200 |

4900x1750x2450 |

5150x1850x2550 |

6500x1850x3650 |

6450x2250x2900 |

6600x2250x2900 |

东莞市高必盛压铸智能装备有限公司,主打锌合金压铸智能装备、自动化设备、包括压铸取件机械手、协作机械手、压铸高速伺服取件机、旋臂自动取件机、双进臂高速喷雾取件机、两轴、三轴横走式取件机、压铸水口全自动分离机、超声波震水口机、超声波抖水口机、多工位模块化自动水口分离机、小披锋冲床、表壳、表带智能自动化加工生产线(钻攻机、去水口机)、输送带、回炉线、回炉上料斗等等其他带PLC技术编程设备.

GS-A3CS 锌合金压铸全自动水口分离机参数与特性

Parameters and characteristics of zinc alloy die-casting fully automatic nozzle separator

|

型号Model No. |

GS-A3CS |

|

适应压铸机Applicable Die Casting Machine |

38-180T |

|

功率Power |

3072W |

|

水口直径 Diameter of Material Shank |

10-35mm |

|

冲压力 Drawing Force |

20kgf |

|

气压源Air Pressure Source |

5-6.5kgf/c㎡ |

|

安装方式Installation Method |

落地式standing type |

|

工件重量 Workpiece Weight |

3kgs |

|

机械重量Machine Weight |

850KGS |

|

外观尺寸External Dimension |

2260*1500*1911mm |

|

适应产品尺寸范围Adapt to product size range |

220*280mm |

|

频率 |

50Hz |

|

电流 |

14A |

|

电压 |

AC220V |

机械特性:

-多工位模块化、选择性工作组合、功能更强大、适应性更广。

-横、竖双向渣包均可以调节式通用夹具就可以去除,省去非标性夹具加工成本。

-加超声波分离产品,对产品保护更好,也更加节约更多的调机时间。

-可选择冲头先折断入料口再超声波,解决入料口比较硬导致的产品难超落分离的问题。

-代替人工分水口,降低生产成本;做到压完即可出货,提高生产效率。

-国家专利产品,弥补国内技术方面的空白。

Mechanical characteristics:

-Multi workstation modularization, selective work combination, more powerful functions, and wider adaptability.

-Both horizontal and vertical slag pockets can be removed with adjustable universal fixtures, saving the cost of non-standard fixture processing.

-Adding ultrasonic separation products provides better product protection and saves more machine adjustment time.

-You can choose to use a punch to first break the feeding port and then use ultrasound to solve the problem of difficult product separation caused by the hard feeding port.

-Replacing manual water distribution to reduce production costs; Ensure that the goods can be shipped after pressing, improving production efficiency.

-National patented products, filling the gap in domestic technology.

东莞市高必盛压铸智能装备有限公司之压铸自动化机械设备产品目录予以参考和选择

高必盛工厂的包装发货展示:

东莞市高必盛智能装备有限公司恭候您的光临。

客服热线:

客服热线:

&tel=13823705126&work=13823705126&email=13823705126@163.com&org=东莞市高必盛压铸智能装备有限公司&adr=东莞市高必盛压铸智能装备有限公司&url=https://yzw.cc/index.php?homepage=dggaobisheng)